Power availability, quality, and reliability are critical inputs into a successful African manufacturing enterprise. Having heard a lot about the falling cost of energy storage solutions, many factory managers are wondering how to take advantage of these new technologies to strengthen their power supply. But the variety of battery energy storage solution (BESS) options can be overwhelming to those new to the market. Luckily, the first step to procuring the best BESS is determining which energy storage applications make the best business case within your facility’s operations. With target commercial outcomes in mind, it’s easier for an energy services provider to identify the most appropriate and affordable storage technology for your situation.

Commercial applications for BESS

Traditional energy storage systems, such as pumped hydro, have been deployed to shift large amounts of energy over long periods of time, offering the benefits of energy arbitrage. But BESS offers customers a wider range of use cases. A BESS employs smaller energy capacities at sub-second response time, rapidly charging or discharging to help existing networks cope with power stability fluctuations. One reason BESS and solar energy systems are often installed together is because a BESS can smooth the integration of intermittent renewable energy sources.

BESS can be designed to provide a variety of services. Some examples include:

- Replacing diesel spinning reserve with battery spinning reserve

Using a BESS in place of diesel spinning reserve reduces generator cycling and specific fuel consumption. Less fuel use reduces fuel costs. In Mali, a gold mine shifted spinning reserve for their 20MW diesel plant to battery energy storage, allowing the diesel generators to run at maximum efficiency without sacrificing the mine’s power reliability. Reduced specific fuel consumption reduced the mine’s overall fuel consumption (and fuel bill) by 10%

- Reducing overall genset runtime, yielding more efficient loading of thermal unit(s) by offsetting with stored energy from another source

In Sierra Leone, a brewery is exploring the integration of a 2MWh battery energy storage system as part of a hybrid solar PV & thermal power system. Reducing generator usage in favour of real-time and stored solar power will help the facility to achieve up to 20% cost savings against its current power spending.

- Smoothing load or supply volatility for more stable power

One of the biggest challenges for sensitive energy uses such as data centres or mining processes is power quality management. The integration of BESS into either existing thermal-powered networks or when adding renewable energy improves the transient response and reduces voltage and frequency disturbances.

Matching desired BESS services to the right technology

The ability of any BESS technology to deliver the desired energy storage service depends on numerous factors: battery cell chemistry and aging characteristics, duty cycle, environmental conditions such as temperature, and proposed project lifetime. A deep understanding of battery technologies, application stack (global duty cycle), operation control (local duty cycle), and systems engineering is needed to design the most efficient BESS configuration!

However, what these technical specifications ultimately determine is how well a BESS technology can deliver either energy services or power services. Energy is how many kWh a BESS can store; the more energy capacity, the more work can be done. Power, on the other hand, is how quickly a BESS can discharge stored energy to be used. Different BESS technologies offer different balances of energy and power capabilities at a given cost. There is no single perfect battery chemistry, so the desired commercial application of the BESS is what drives the choice of appropriate BESS technology.

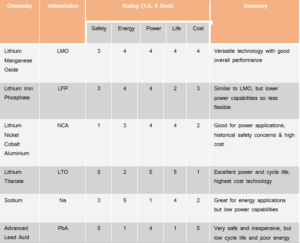

See below for a listing of common BESS technologies and brief comparisons of their energy and power capabilities.

For example, utilities seeking grid scale BESS prioritize having have the most energy readily available to balance frequency and ensure available energy distribution. For this use case, sodium-ion BESS technology can be a good match, as this battery capacity optimizes for energy capacity and has a relatively good lifetime.

On the other hand, power systems for commercial-industrial operations such as mining, manufacturing, or data centres may be optimized for running specific equipment with sensitive thresholds. A BESS in this context needs to be fast enough to ensure rapid transient response to power fluctuations to maintain power reliability and quality. In this case, lithium-ion BESS technologies are often well-suited; 90% of lithium-ion BESS are currently deployed in commercial-industrial applications.

Facilities that can successfully identify how BESS will save their business money – whether through reducing the cost of specific fuel consumption or improving power quality management – are best-positioned to receive the most competitive, practical BESS quotes. The suite of commercially available BESS technologies is always changing, but this variety means energy service providers can offer clients many ways to balance technological and commercial trade-offs.

Questions about how to establish a business case for energy storage? Or comments on how we’ve classified BESS technologies? Contact Jean-Philippe, Kathleen, and their CBE colleagues at CBETech@crossboundary.com